As a leading manufacturer of Air Fittings, we pride ourselves on delivering top-notch products that meet the highest standards of quality and performance. We have established ourselves as a trusted exporter in the industry, known for our dedication to excellence and customer satisfaction.

Air Fittings

Reusable Hose Fittings for Air Brake Hose

Applications:

Used with SAE J1402 rubber hose Type A in air brake system, except for where temperature is under -40°F(-40°C) or above +212°F(+100°C) or where battery acid can drip on tubing.

Advantages:

Meet D.O.T. FMVSS 571.106 air brake specifications.

Meet functional requirements of SAE J1402.

Easy to assemble and disassemble

Reusable (body and nut are reusable)

Notes: When reassembling fittings and hoses, the fitting body and nut should be inspected.Only if the parts are in proper condition, can they be reused. SLEEVE SHOULD BE NEVER REUSED.

Material: C36000 brass

Finish: Plain

For 3/8 and 1/2 Rubber Hose

1/4”NPTF, 3/8”NPTF, 1/2”NPTF are available

Reusable hose ends are a great solution for those who need to repair or replace their SAEJ1402 air brake hose. These hose ends are designed to be used with the specific type of hose and are reusable, making them a more sustainable option than traditional crimped hose ends.

One of the benefits of reusable hose ends is that they allow for easy installation and maintenance of the hose. They can be assembled quickly and easily with a few simple tools and without the need for specialized equipment. This means that the hose can be repaired on-site, reducing downtime and costs associated with replacing the entire hose assembly.

Overall, reusable hose ends for SAEJ1402 air brake hoses offer a range of benefits that make them an excellent choice for industries that require reliable and long-lasting hose connections. They are easy to install, durable, and environmentally friendly, making them a smart choice for anyone who needs to repair or replace their air brake hoses

Air Brake Push to Connect Fittings

Applications:

Used with SAE J844 Type A and Type B nylon tubing in air brake system, or in cab air controls, except for where temperature is under -40°F(-40°C) or above +200°F(+93°C) or where battery acid can drip on tubing.

Advantages:

Material: Brass, EPDM O Ring

Meet D.O.T. FMVSS 571.106 air brake specifications

Easy and fast assembly by hand, no special tools asked

Reusable: connect and disconnect numerous times

Pre-applied Teflon: loctite 516 on male pipe

Positive Seal: After tubing is inserted, seal is made no leakage

Pressure Range: Vacuum to 150PSI

Temperature Range: -58°F to 302°F (-50°C to 150°C)

Air brake push-to-connect fittings are an important component of any air brake system. They are DOT compliant, meaning they meet the safety standards set by the Department of Transportation. These fittings are designed to connect the brake lines in a vehicle's air brake system, allowing for efficient and effective braking.

The push-to-connect design of these fittings makes them easy to use and install. They work by simply pushing the tube into the fitting until it clicks into place. The fitting uses a collet to hold the tube securely in place, ensuring a tight and leak-free connection.

One of the advantages of using air brake push-to-connect fittings is that they eliminate the need for special tools or expertise. Anyone can install them, even those with no previous experience with air brake systems. The fittings are designed to be intuitive and easy to use, which makes them an ideal choice for DIYers and professional mechanics alike.

Another advantage of these fittings is their versatility. They come in a wide range of sizes and configurations (unions, connectors, 45°elbow, 90°elbow, fixed or swivel, run tee, branch tee), allowing them to be used in a variety of applications. Whether you need to connect brake lines in a truck, bus, or other type of vehicle, there is a push-to-connect fitting that will meet your needs.

Finally, air brake push-to-connect fittings are incredibly reliable. They are designed to withstand the high pressures and temperatures that are typical in air brake systems, and they are built to last. When you use these fittings, you can have confidence that your brake system will function properly and safely.

In summary, air brake push-to-connect fittings are an essential component.

D.O.T Air Brake Brass Fittings

DOT NTA brass fittings for air brake systems are an essential component of air brake systems. They are used in conjunction with SAE J844 Type A and Type B nylon tubing, as well as in-cab air controls. These fittings are ideal for use in most air brake systems, with the exception of those where the temperature is under -40°F(-40°C) or above +200°F(+93°C), or where battery acid can drip on the tubing.

One of the main advantages of DOT NTA brass fittings is that they meet D.O.T. FMVSS 571.106 air brake specifications. This means that they are designed to meet the highest standards for safety and reliability in air brake systems. Additionally, these fittings meet the functional requirements of the SAE 246 & SAE J1131, ensuring that they are compatible with other components of air brake systems.

DOT NTA brass fittings are machined from CA360 brass, which is a high-quality, corrosion-resistant alloy that is well-suited for use in air brake systems. This material is strong and durable, making it ideal for use in harsh environments where it may be subjected to high pressures, vibration, or temperature extremes.

Another significant advantage of DOT NTA brass fittings is that they are easy to assemble. They do not require any tube preparation or flaring, and they come with a built-in tube support to help ensure a secure fit. This makes them ideal for use in situations where time is of the essence, or where assembly must be done quickly and efficiently.

In summary, DOT NTA brass fittings are a reliable, high-quality component of air brake systems. They meet the highest safety and reliability standards, and are compatible with other components of air brake systems. Their use of durable materials and ease of assembly make them an ideal choice for many applications.

Air Brake Metric Push In Coupling

Air Brake Metric Push In Coupling is an essential component used with DIN74324 or DIN73378 tubing, which are widely adopted in the compressed air circuits of commercial vehicles. Crafted from brass and fortified with an EPDM O-Ring, these couplings are not only robust but also perform exceptionally well under harsh conditions, with an operating temperature range of -40°C to +100°C.

A salient feature of this coupling is its user-friendly design that facilitates easy and quick assembly . The coupling is designed for maximum flexibility, with the capacity to be connected and disconnected multiple times, demonstrating its reusable nature.

The coupling ensures a high level of reliability with a positive seal. Once the tubing is inserted, a tight seal is formed that prevents any leakage, making it a highly reliable solution for your pneumatic applications. However, it is crucial to note that the use of these couplings with media other than air is strictly not advised without prior approval.

Overall, the Air Brake Metric Push In Coupling is a trustworthy, durable, and versatile solution for maintaining efficient air circuits in commercial vehicles.

Our extensive range of

We believe in delivering the best products to our customers, which is why we use only premium materials and state-of-the-art manufacturing processes. Each fitting undergoes rigorous testing to ensure it meets our stringent quality standards, providing you with the assurance of reliability and longevity.

At our core, we are committed to innovation and continuous improvement. Our team of experts constantly explores new technologies and techniques to enhance our product offerings, ensuring that we stay ahead of the curve in the ever-evolving industry.

Choosing us means opting for excellence, reliability, and superior service. We take pride in our ability to meet the diverse needs of our global clientele, offering customized solutions that align with specific requirements.

In addition to our high-quality products, we also provide exceptional customer support. Our knowledgeable team is always ready to assist you with product selection, technical support, and after-sales service, ensuring a smooth and satisfying experience from start to finish.

Experience the difference with our

Air Fittings

is designed to cater to various industrial needs, ensuring optimal performance and reliability in every application. Whether you require fittings for pneumatic systems, hydraulic applications, or other air-related uses, our products are engineered to provide seamless connections and durable performance.We believe in delivering the best products to our customers, which is why we use only premium materials and state-of-the-art manufacturing processes. Each fitting undergoes rigorous testing to ensure it meets our stringent quality standards, providing you with the assurance of reliability and longevity.

At our core, we are committed to innovation and continuous improvement. Our team of experts constantly explores new technologies and techniques to enhance our product offerings, ensuring that we stay ahead of the curve in the ever-evolving industry.

Choosing us means opting for excellence, reliability, and superior service. We take pride in our ability to meet the diverse needs of our global clientele, offering customized solutions that align with specific requirements.

In addition to our high-quality products, we also provide exceptional customer support. Our knowledgeable team is always ready to assist you with product selection, technical support, and after-sales service, ensuring a smooth and satisfying experience from start to finish.

Experience the difference with our

Air Fittings

and see why we are considered the best in the industry. Contact us today to learn more about our products and how we can serve your needs as a leading supplier from Taiwan.

What is Air Fittings?

The most commonly used industry term for air hose fittings is quick disconnect (or quick connect). Having durable and reliable air tool fittings and air tool couplers is hugely important for the safe and efficient operation of your air tools. The fittings maintain a constant flow of air and pressure within the hoses so that the performance of the air tools is not compromised. Common applications include frame to axle air lines for heavy duty trucks and trailers.

Our range of couplings and adaptors for air tools include Air Brake Brass Fittings, DOT Air Brake Fittings, DOT Push To Connect Air Fittings, Metric DIN Fittings, Air Brake Hose Fittings, Tractor Trailer Air Hose Connectors, Air Brake Hose and Tractor Trailer Air Lines. D.O.T. push-to-connect fittings are faster and easier to install and disassemble in the compact spaces where air brake hoses run. They are easily connected by hand, by simply pushing the tube or hose into the fitting; they provide a leak free seal.

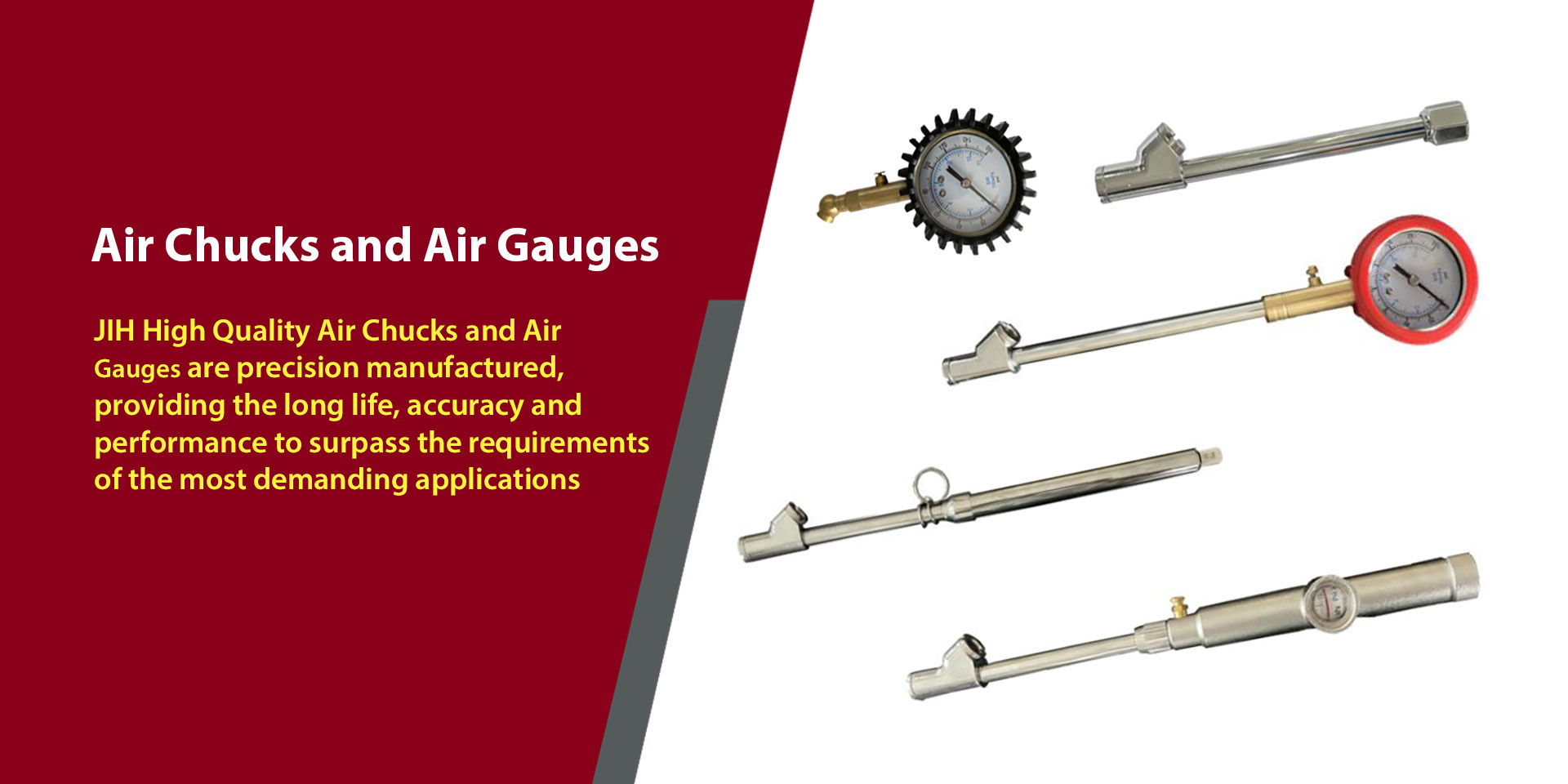

As a professional manufacturer and exporter of Air Fittings, we also produces a variety of high-quality Tire Pressure Gauges, Air Chucks, Air Receiver Tank and Air Parts for customers to choose. That will let you achieve optimum tire air pressure quickly and easily. We have been working with some esteemed brands. Moreover, our products are sold worldwide successfully. If you are looking for suppliers and long-term partnership, welcome to contact us.

The most commonly used industry term for air hose fittings is quick disconnect (or quick connect). Having durable and reliable air tool fittings and air tool couplers is hugely important for the safe and efficient operation of your air tools. The fittings maintain a constant flow of air and pressure within the hoses so that the performance of the air tools is not compromised. Common applications include frame to axle air lines for heavy duty trucks and trailers.

Our range of couplings and adaptors for air tools include Air Brake Brass Fittings, DOT Air Brake Fittings, DOT Push To Connect Air Fittings, Metric DIN Fittings, Air Brake Hose Fittings, Tractor Trailer Air Hose Connectors, Air Brake Hose and Tractor Trailer Air Lines. D.O.T. push-to-connect fittings are faster and easier to install and disassemble in the compact spaces where air brake hoses run. They are easily connected by hand, by simply pushing the tube or hose into the fitting; they provide a leak free seal.

As a professional manufacturer and exporter of Air Fittings, we also produces a variety of high-quality Tire Pressure Gauges, Air Chucks, Air Receiver Tank and Air Parts for customers to choose. That will let you achieve optimum tire air pressure quickly and easily. We have been working with some esteemed brands. Moreover, our products are sold worldwide successfully. If you are looking for suppliers and long-term partnership, welcome to contact us.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk